Creating an Engineering Club from an Idea

Isabela Castillo, E’25, bioengineering, came to Northeastern University with an idea to create prosthetic hands and led to her starting Give a Hand, a club developing low-cost, 3D-printed prosthetic hands.

This article originally appeared on Northeastern Global News. It was published by Schuyler Velasco. Main photo: Isabela Castillo works on a 3-D printed prosthetic hand in the EXP Makerspace on the Boston campus. Castillo is a third year Northeastern bioengineering student who heads up Give A Hand, a club developing low-cost prosthetic hands with 3-D printing. Photo by Alyssa Stone/Northeastern University

The future of prosthetics is 3D-printed. This student has a hand in it

All universities work hard to attract students. But it’s difficult to imagine a more compelling sell than the one Northeastern University gave Isabela Castillo.

In the spring of 2021, Castillo had been accepted to Northeastern, but she was still deciding on a U.S. college when she and her parents visited campus from their home in Mexico City. “It was a last-minute decision to come, and we couldn’t get a tour,” Castillo remembers. “We were standing in ISEC alone, looking up at the building. And suddenly Joseph Aoun was there.”

The Northeastern president had been passing through the campus’s Interdisciplinary Science and Engineering Complex, and he began peppering Castillo with questions. “‘What are you doing here?’ ‘Where are you from?’ ‘What do you study?’” she recalls. She said she was interested in bioengineering. Aoun grabbed his phone and called up Lee Makowski, the chair of the bioengineering department.

Before she knew it, Makowski was giving her a personal tour of the engineering school. “I was shocked,” she says. “Like, I have to come here.”

When she enrolled the following fall, Castillo brought along a project she had been tinkering with in Mexico. Stuck in her house during the COVID-19 pandemic — which closed Mexico’s schools for much longer than in the United States — she began building prosthetic hands.

In the two years since, the project she started alone in her childhood bedroom has grown into Give a Hand, an engineering club at Northeastern devoted to developing low-cost, custom prosthetic hands, primarily for children, using 3D-printed materials.

|

|

|

|

Photos by Alyssa Stone/Northeastern University

Castillo started the club after her freshman year with Valeria Solorzano, a high school friend and pre-law major, and Paul Maurin, who she met in one of her first engineering classes. At first, they worked on a donated 3D printer in the middle of Solorzano’s apartment floor. The club now has about 70 members and access to the makerspace in the EXP research complex on the Boston campus.

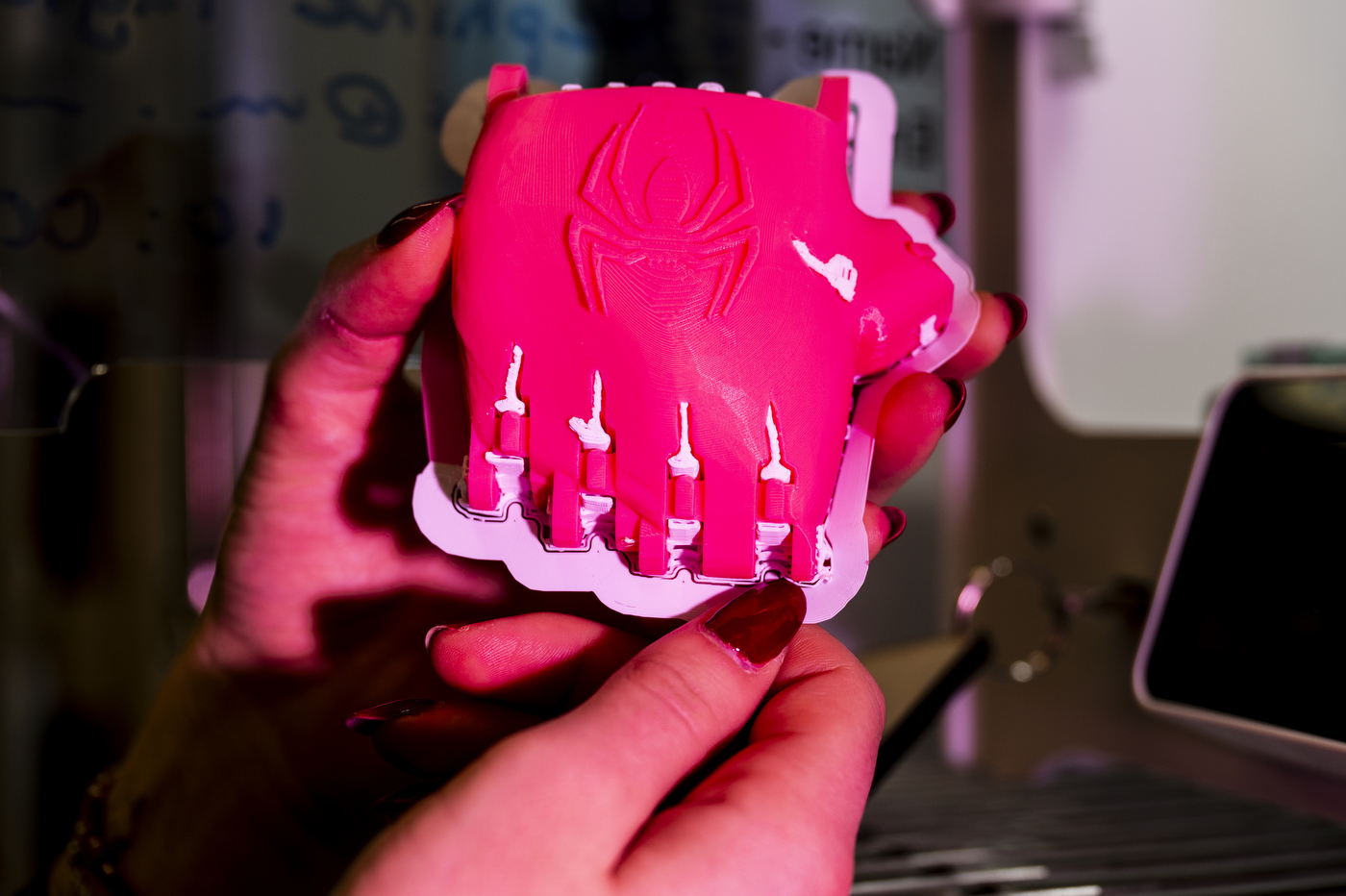

There, in between wrapping up her last week of classes in December, Castillo demos a prototype hand that fits over the wrist. It’s pink and purple, sized for a child in mid-elementary school; a Spider-Man design is etched on the back of the palm. The wrist attachment, palm, articulated fingers and joints are fresh from one of the printers in a dedicated room in the makerspace.

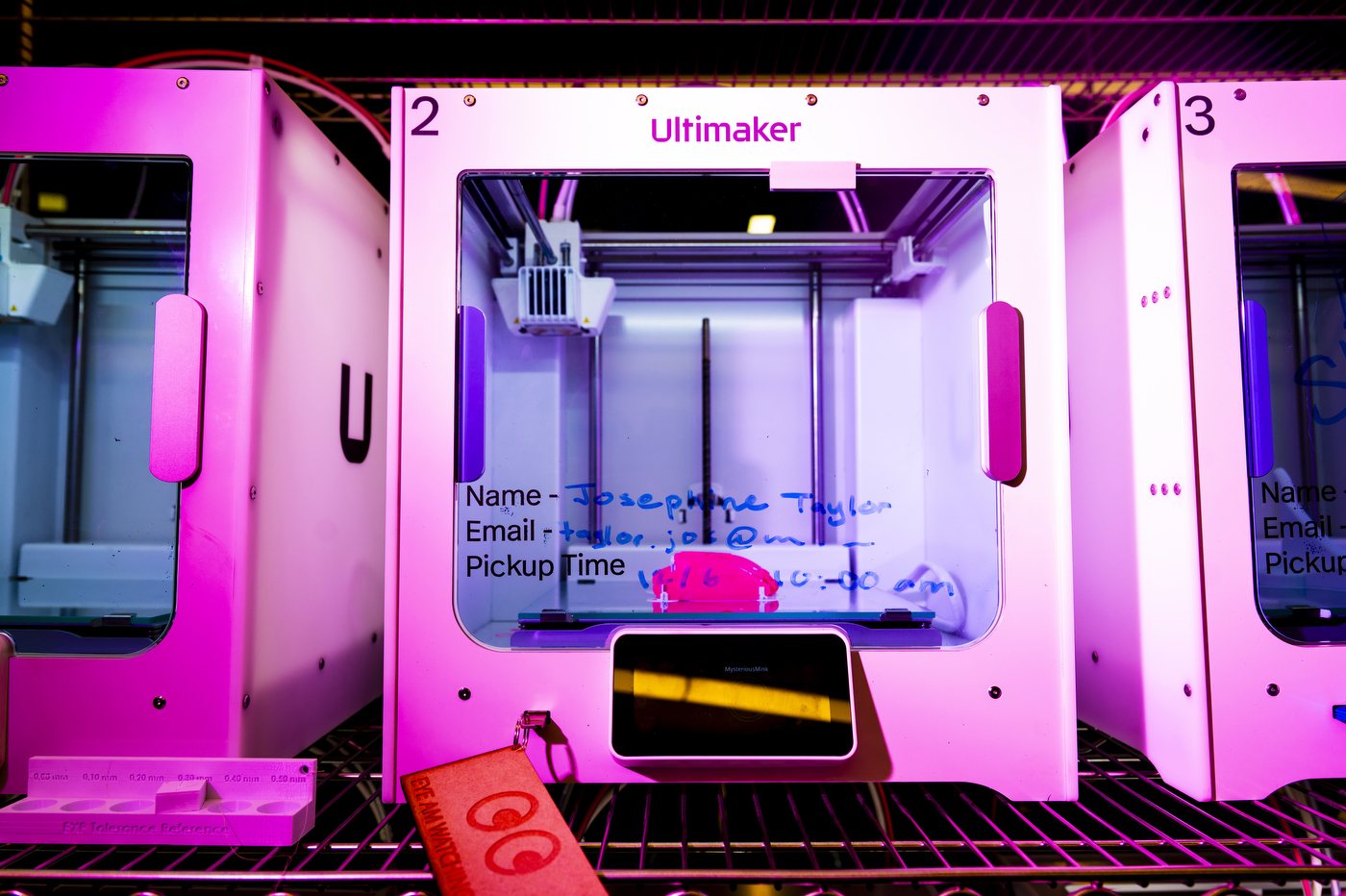

The printers, which look like small farm incubators, are stacked on metal shelving, humming away at projects labeled in dry-erase marker on their glass doors. Working off a computer blueprint, a 3D printer can manufacture a hand’s component parts from plastic filament in about 3 to 8 hours’ time, depending on the design. Castillo then puts them together manually, using metal screws and hand-sewn wire.

Read full story at Northeastern Global News